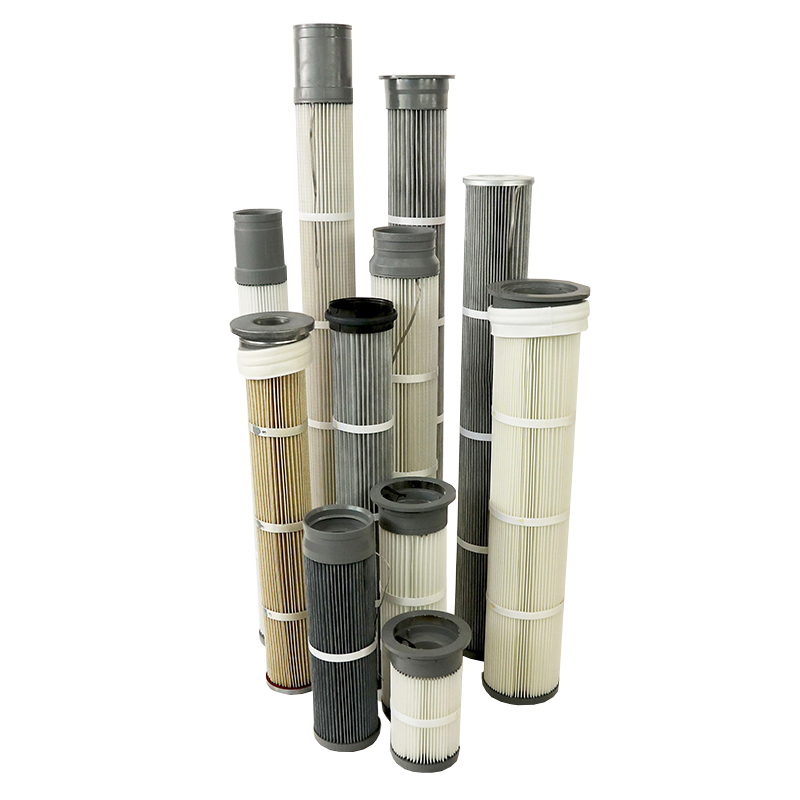

Our pleated bags are engineered and designed to fit most OEM-style Pulse-Jet Baghouses. As a cost-effective alternative option to fabric bags and cages, our pleated bags are manufactured in the USA. Easy to install and lasts longer than fabric filter bags. Common replacements for many brands including:

- Mikropul

- Flex-Kleen

- MAC

- Camcorp

- C&W

- IFIL

- BHA/Parker

- AJR & Many More!

- Engineered designs to fit most OEM-style Pulse-Jet baghouses

- Cost effective alternative to fabric bags and cages

- Top and bottom load designs

- Up to 2 to 3 times the filter life over fabric filter bags

- Various engineered pleat geometries

- Multiple construction styles

- Efficiencies of up to 99.99%

- Rigid physical media properties

- Reduces downtime and maintenance cost

- Promotes surface filtration & dust release

- Patented design offers easy installation

- Fiber: 100% Spunbond polyester

- BIA Rating: U,S,G, & C

- Media Efficiency: 99.5% at 1 micron and above

- Air Permeability: 20 cfm @ 1/2" w.g.

- Thermal Stability: 2% maximum @ 275%

- Maximum Operating Temperature: Rating is 200°F for finished elements. Higher temperature rating available

Customer Feedback

“For years my company has relied upon the superior quality, engineering and quick turnaround times of Apel filtration. Now under the Pleatco banner, the service has continued and is head and shoulders above any of the other solution providers out there.”

Let Us Work with You

For customer convenience, we stock thousands of popular OEM style filters at our manufacturing facility, which can ship in 24 hours. You can also arrange for our highly trusted private labeling, drop-shipments, and blanket order programs. Regardless of size, we provide all our customers with answers to their technical questions, develop workable cost-effective solutions for their filter problems, and provide them with filters from our full range of standard and custom products.

Media Options

We offer a variety of media options including Cellulose Polyester, Spunbond, Nano, and more!

MediasBuild Your Filter

Custom Engineering & Specialty Filters

Let us work together to build the perfect product you wish to engineer for your special application, project or customer. We’ll flesh out the basics here and one of our filter pros will help get it quoted, built and into the field ASAP.

Let's Go!