Gas Turbine Filters

A wide range for all styles of filter house systems

Harsh weather conditions, high levels of airborne particulates and salt ingress are just some of the challenges faced by gas turbine operators in the oil and gas industry. Often sited in remote locations, gas turbines used in the oil and gas industry typically encounter extremely challenging operating environments. High levels of small particulates in the form of sand, dust and shot debris from drilling, salt aerosols in offshore and coastal locations, and harsh weather conditions all threaten the performance and health of a gas turbine.

Pleatco OEM replacement gas turbine filter cartridges assure maximum operating efficiency of a gas turbine. Air inlet filtration is a critical element to assure maximum operating efficiency. Properly selecting and maintaining the filtration system can increase the performance and extend run time of the gas turbine as well as minimize unplanned maintenance associated with unexpected filter failure. Different styles of filter houses require different types of filtration. Proper filter / component selection should include consideration of environmental factors such as ambient dust concentration; humidity; intense periods of moisture such as fog, rain, and snow; and the durability required over the life of the filter.

With Pleatco’s top-rated customer service and expert technical support, we’ll carefully assess your filtration needs and construct a standard or custom filter for you. The results of our labor will be reflected in the efficient performance of your operating systems with high efficiencies and minimum downtime.

- Long-Term Savings

- Extended Filter Life

- Lower Pressure Drops

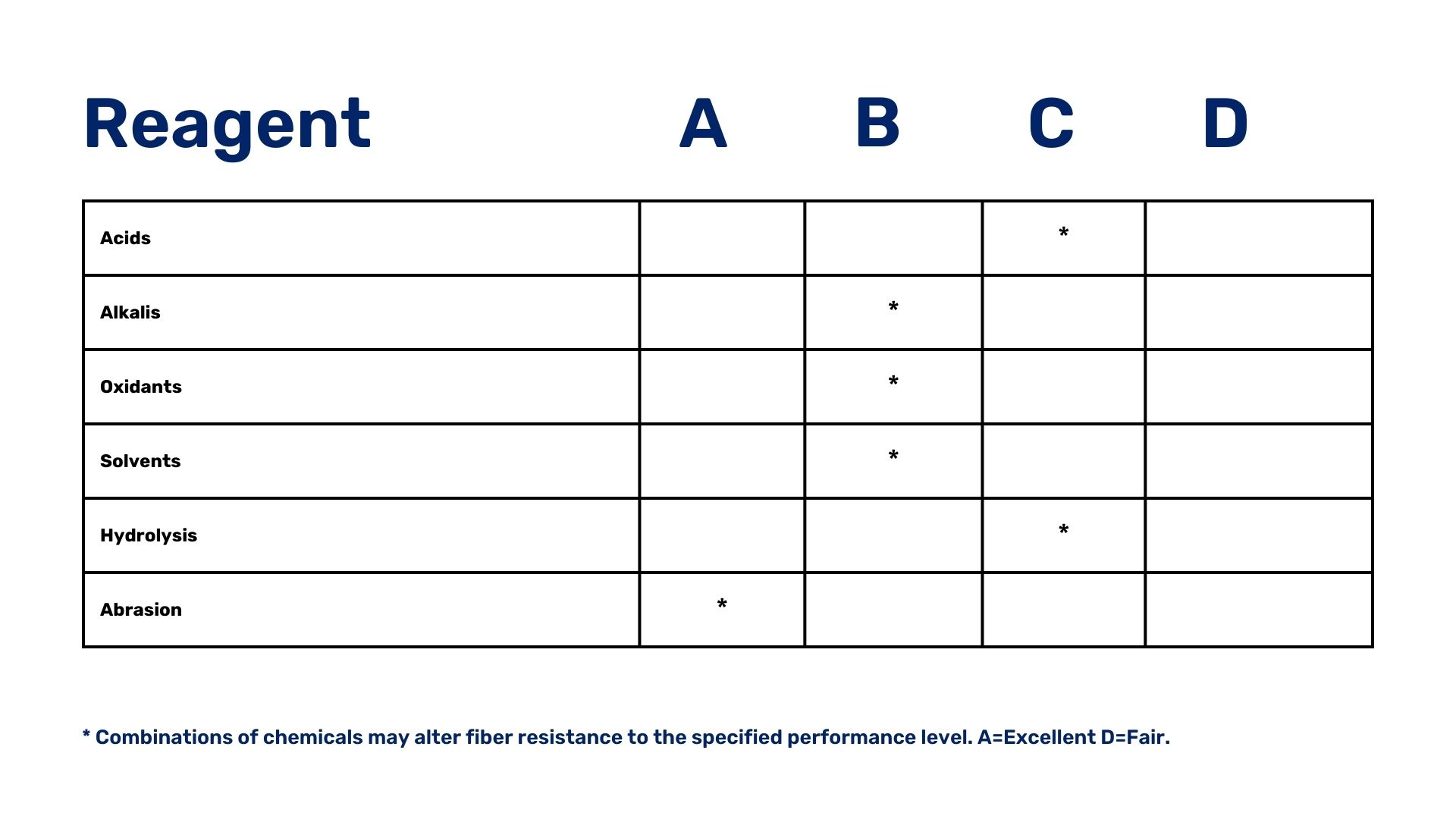

- Abrasion & Chemical Resistant

- Reduced Compressed Air Usage

- Fiber: 100% Spunbond polyester

- BIA Rating: U,S,G, & C

- Media Efficiency: 99.5% at 1 micron and above

- Air Permeability: 20 cfm @ 1/2" w.g.

- Thermal Stability: 2% maximum @ 275%

- Maximum Operating Temperature: Rating is 200°F for finished elements. Higher temperature rating available

100% Spunbond Polyester Media

- Water & Oil Repellencies

- Aluminization for static control

- Carbon Impregnated

- PTFE Membrane Laminates

- Carbon Aramid Felt

- PPS

Optional Construction for a Wide Variety of Applications and System Design:

- Lightweight media core

- Heavy-gauge media core

- Stainless & galvanized components

- Urethanes, Epoxies, EPDM & Silicone

- Carbon Aramid Felt

- FDA grade construction

Temperature Ratings:

- Spunbond: 180°F - 265°F

- Aramid/ PPS: 375°F

- Higher temperature construction available

Customer Feedback

“For years my company has relied upon the superior quality, engineering and quick turnaround times of Apel filtration. Now under the Pleatco banner, the service has continued and is head and shoulders above any of the other solution providers out there.”

Let Us Work with You

For customer convenience, we stock thousands of popular OEM style filters at our manufacturing facility, which can ship in 24 hours. You can also arrange for our highly trusted private labeling, drop-shipments, and blanket order programs. Regardless of size, we provide all our customers with answers to their technical questions, develop workable cost-effective solutions for their filter problems, and provide them with filters from our full range of standard and custom products.

Build Your Filter

Custom Engineering & Specialty Filters

Let us work together to build the perfect product you wish to engineer for your special application, project or customer. We’ll flesh out the basics here and one of our filter pros will help get it quoted, built and into the field ASAP.

Let's Go!